Dynamic / Shaping the future

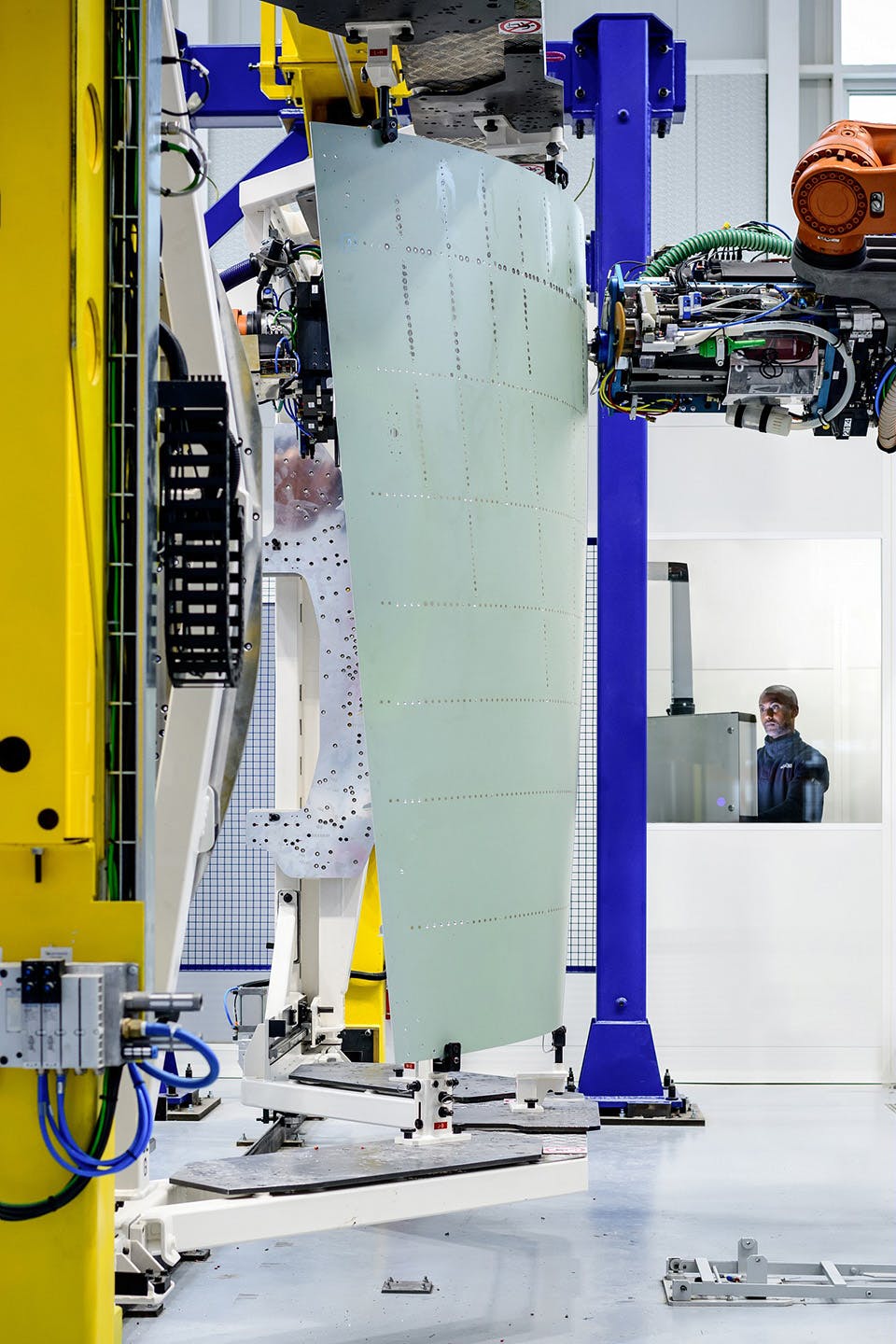

Adapting our manufacturing resourcesAdapting our manufacturing resources

Our ongoing efforts to enhance both our manufacturing processes and our production ecosystem are key to achieving the high levels of quality and competitiveness demanded by the global market. Our manufacturing system is focused on the adjustment of our supply chain and the expansion of our international operations.

Made in India

The 2016 contract for 36 Rafales has strengthened our over 70-year relationship with India thanks to an increased sharing of workloads and technologies, resulting in sustained benefits in terms of competitiveness. Since 2020, our Nagpur plant, located in Maharashtra, has been producing Falcon 2000 front fuselage sections. The ramp-up in production has resulted in the addition of a second 135,000-sq-foot production facility.

Our fully operational Pune facility, Dassault Aviation Services India - Engineering Center (DASI-EC), has just celebrated its fifth anniversary.

Growing Indian supply chain

We are working actively to develop the Indian supply chain, by expanding our network of local partners. We have qualified major new Indian subcontractors, most notably Dynamatic (for the manufacture of the Falcon 6X T5 section fuel tank and the supply of primary parts) and Aerolloy, a subsidiary of the PTC Group (for development of a titanium foundry).

Ramping up production

We have put in place a centralized management system to facilitate the ramping up of production, and to support to some of our subcontractors as we pursue our Make in India strategy.

All our plants are managed using a centralized Operational Performance System (OPS), which is also utilized by our key suppliers in the interest of enhancing overall resilience.

Investment in our industrial infrastructure

We are continuing to invest, in particular to pave the way for the advent of the new Falcon 10X: a building to house its simulator, in Istres; a building devoted to wing box systems, in Martignas; new buildings to handle the assembly and fitting out of all Falcon fuselages, as well as the final assembly of the Falcon 10X, in Mérignac; and two new buildings (painting and Falcon 10X) in Little Rock. Our Cergy plant was completed in 2024, and has taken over from its predecessor in Argenteuil. The first aircraft sections have already rolled off the production line at the new facility.